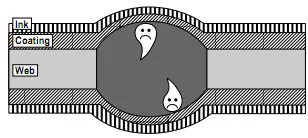

Definition: This happens when moisture cannot escape the paper through the porous coating. When it causes a small bubble upon exiting the heatset dryer oven, this is called blistering.

Problem: Printing heavyweight coated stock.

Description: The thicker the paper, the more moisture must escape. There is only so much surface area to do so. The increased amount of moisture in thicker papers combined with the fact that they are coated, allows less opportunity for moisture to escape in the drying process.

Solution: Run at the minimum dryer temperature required. If that doesn't work, slow down the press. Oven length is the determining factor as to how well a press will run this type of stock.

Problem: High moisture content paper.

Description: Too much moisture is in the paper. Once again, on coated stocks, this problem will show up more often.

Solution: A paper moisture content reader is expensive. If you have one, check it against the paper manufacturer's specs. Ultimately this is an issue you will have to take up with the paper company. In the meantime, lower your speed and/or oven temperature.

Problem: Image areas tend to blister.

Description: What area is available for the moisture to escape is plugged by ink. This especially becomes apparent when you are running solids on both sides of the web.

Solution: Lower the denisty to minimum allowable. Run dryer temp lower and/or press slower.

I can't find my problem.

Start Over :Web Press Troubleshooting Guide

Problem: Printing heavyweight coated stock.

Description: The thicker the paper, the more moisture must escape. There is only so much surface area to do so. The increased amount of moisture in thicker papers combined with the fact that they are coated, allows less opportunity for moisture to escape in the drying process.

Solution: Run at the minimum dryer temperature required. If that doesn't work, slow down the press. Oven length is the determining factor as to how well a press will run this type of stock.

Problem: High moisture content paper.

Description: Too much moisture is in the paper. Once again, on coated stocks, this problem will show up more often.

Solution: A paper moisture content reader is expensive. If you have one, check it against the paper manufacturer's specs. Ultimately this is an issue you will have to take up with the paper company. In the meantime, lower your speed and/or oven temperature.

Problem: Image areas tend to blister.

Description: What area is available for the moisture to escape is plugged by ink. This especially becomes apparent when you are running solids on both sides of the web.

Solution: Lower the denisty to minimum allowable. Run dryer temp lower and/or press slower.

I can't find my problem.

Start Over :Web Press Troubleshooting Guide

Comments

Post a Comment