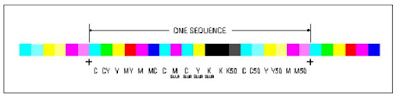

A print control strip from GATF or Fogra is an excellent quality control measure on an offset printing press. There are many varieties, but I want to share with you the one that we use. We have actually customized it a little, so the one shown above is not the exact print control strip that we use. However it is close and I will go over each patch on it and tell how we use it.

Where are print control strips located on a press sheet?

Usually right close to the cylinder gap. This is because these are is going to be trimmed. It will also not be folded and so it makes for easy scanning. Ours are located on the tail edge of the sheet. We put the strip on the tail edge because we use a web press and the lead edge will get punctured by pins.

Before it gets to the press...

Back in the days of film, control of strips on the plate were critical. Overexposure would ruin it. Nowadays it is still necessary, but more dummy-proof with plate image setters.

Prepress departments have special scanners that will detect if the 80 percent screen is really 80 percent. This part of quality control is essential for it to have any meaning on your offset printing press.

Before we break it down, we must understand that the print control strip above repeats itself and has several sequences. Here is an example of one sequence:

So it's really not all that daunting. When doing a printing test to see the performance of a press, the print control strips get much more complicated. That is not what we are considering here. I'm showing you what we use under running conditions when the pressman needs fast feedback of what's happening inside the press. Here we go.

Density

|

| Print control strip - density. |

This is the most used and basic part of the control strip. They are primarily meant to check for ink density. No screen value, no ink overlay, just density control. Any offset printing press room should have access to a densitometer for this. We use a spectrophotometer which will also tell you the same.

Trapping

The next in sequence at the top of the page is an orange/red patch. It is meant to check for trapping. The picture above shows all three overlay colors. If possible, these are placed very close to the CMY density patches. This is so that the density readings match the density laid down for these trapping measurements.

But I must object. This print control strip from Fogra is not very good. It does not have patches for green, blue and read. Not the one at the top of this artilce anyways. This is why we have customized our strip for our own offset printing needs.

We use the one pictured above. A red, green and blue strip in each sequence.

Grayscale

This is a great visual to see that the color inks are balanced. Ideally you are targeting a neutral grey. Of course, measuring density of the solid patches will get you close. But these are a great way to get a quick and highly sensitive visual on the color balance. To a certain extent this will tell you about trapping since it is also an overprint of cyan, magenta and yellow.

It is noteworthy that this patch on the control strip is not equal parts cyan, magenta and yellow. It simply has just the right screen values to produce gray. Match this and you match the color images on your offset printing press.

Register

I have never used this patch from a control strip before, but it looks effective. All three colors lay down to form black/grey. If there is a shift in the register, the color will show distinctly in this box.

Slur

Just a slight shift, circumferentially or laterally, will blur it or turn part of the patch solid. The bottom straight lines will blur if it's a circumferential slip against the blanket. The upper ones will slur on both.

Caution: If you have automatic register, adjustments will be made while the press is running. The plate cylinder will move and cause a slight slur. You need to check multiple copies to see if the slurring is really the problem.

Web growth

This is for web offset printers. This is also a big shortcoming of the print control strips that are out there for web printers. A special control strip patch is necessary. Because of tension between the printing units, the paper stretches and grows in width. This wreaks havoc on register control. Hence the image on each successive plate must be made a little bigger.

Therefore at the very edges of the web on the print control strip there must be something to check register.

If you are a web printer then you need a patch on the control strip that can help you to do plate cocking and make adjustments for web growth in your prepress. Below is an example of what it should look like:

So you see, this is why we make our own custom print control strips for our offset printing presses.

Ink density, gain and slurring

This is not shown on the print control strip above, but it is very valuable for offset printers. A printer can make a quick visual and see if they are running too much ink. When starting a new print job we will quickly check these patches to see if they are filling in.

Slurring also shows up on this patch as the sides or top/bottom can fill in.

Additionally, if there is too much pressure between the plate, cylinder or blanket, it can show up here.

Dot gain

The 40/80 screens are typically the best for determining a rudimentary dot gain curve. Some print control strips will simply have a 50% screen. That works too. The reading must be taken with a densitometer for any kind of accuracy.

Conclusion

If you want to really get into depth on these control test strips for offset printing, you need to take a close look at a fingerprint test. Here I just wanted to go over what the press operator is looking at that can be useful while running. Hope you enjoyed.

Comments

Post a Comment