First, let's make sure we are all on the same page and understand what UV printing is.

What is UV printing?

This is becoming very popular lately among newspaper printers. The newspaper that used to stink now have a beautiful gloss look, odor free and nothing rubbing off on your hands. This is all thanks to UV cured inks.

It is gaining popularity as there were many concerns about the environment and health of the press operators. Because of advancements in the formula and process, these concerns have all but disappeared.

How do UV inks work?

UV inks work by utilizing ultraviolet radiation to dry printing ink. UV light is a product of our sun, and in very small amounts is harmless. However this spectrum is magnified to dry printing inks between the light wavelengths of between 100 and 380 nanometers.

This spectum is barely visible as the human eye is only able to pick up light starting at around 380 nanometers.

Notice in the illustration above that there are four bands of UV light:

EUV - Stands for Extreme Ultraviolet light. (10–180 nm) Though this band of light is available to the printing industry, there are fewer than 50 printing companies that use it in the world. This extreme light has very limited applications in printing.

UVC - Stands for Ultraviolet light C band. (180–280 nm) This area of the spectrum ensures immediate curing of the ink. It doesn't have the penetrating power of the deeper layers, but ensures a quick and cured surface of the printing ink layer.

UVB - Stands for Ultraviolet light B band. (280–315 nm) This wavelength goes deeper into the ink. For this reason it is more effective than UVC.

UVA - Stands for Ultraviolet light A band. (315–400 nm) This is the spectrum utilized most by offset printing presses. Hence there is a visible glow to the lights as the human eye is able to pick up this light. It penetrates and dries deeper and is well suited to offset printing presses that apply thicker ink films to paper.

The advantages of UV offset printing

Better for the environment. The energy savings are significant. Many drying systems require direct heat which consumes a lot of energy. The UV curing method requires much less, just the electricity to power the lamps.

The entire UV curing system is also VOC free. No harmful emissions are released. This requires no exhaust system during the curing process and results in no health or safety risks to press operators.

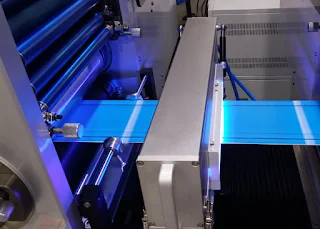

Lower printing press footprint. The lamps simply install between the printing units. There is no need to add a dryer at the end of the press. Some heatset printing presses require a very long hot air dryer. In this case the length of the offset press can be reduced by almost a third.

Works on almost any substrate. UV inks can be used on almost any surface such as the following:

- glossy paper

- matte paper

- cardboard

- metal substrates

- plastic films

- glass

This includes different sizes of substrates such as large sheets or narrow webs.

Ink remains fresh. Offset printers report that the ink does not skin in the fountain as long as it's not exposed to UV light. Ink piling on the blanket is also reported to be significantly less. Once the ink is cured right after it leaves the printing unit, it will not back-trap onto the next unit. This makes trapping inks a non-issue on color printing.

Gloss levels are higher. The conventional offset process can achieve a glossy finish, particularly on coated paper. However a higher level of gloss is achieved with UV inks. This is a seller for advertisers who are looking to add punch to their ads.

Less anti-setoff powder is required. Because the ink is cured, there is no almost setoff. Press operators report that they can go without setoff powder, or use extremely little.

Faster production speeds. The curing process is extremely fast and therefore allows the press to run much faster, not worrying about setoff.

The disadvantages of UV offset printing

Skin irritation. Press operators report skin irritation when handling the ink. Manufacturers generally report low toxicity, however care needs to be taken to not allow the ink to come in contact with skin. Safety data sheets recommend wearing skin and eye protection.

Initial startup costs. UV curing lamps are expensive. They last a long time, but burn out after a while. This ongoing cost must be considered.

The ink doesn't dry without UV light. If a lamp goes out while running it can make a mess on the press. The ink only dries with UV light.

Conclusion

Having said all of this, you may wonder why all offset printers do not switch to UV inks. The truth is that many are. It will just take time to see it's full impact.

Thanks for sharing this one.

ReplyDelete